Refractories

the Types of refractory materials

Fuerte offers a wide range of refractories products providing exceptional performances in a wide range of applications such as Mortar, firebricks, Castables and so on, check belows, you will find more details

Mortars

Heat-resistant mortar, is a specialized type of mortar used for bonding and sealing refractory bricks and other refractory materials in high-temperature environments. It is designed to withstand extreme heat, thermal shock, and exposure to aggressive chemicals. Refractory mortar plays a crucial role in creating durable and stable linings for industrial furnaces, kilns, boilers, and other high-temperature equipment

Firebricks

Refractory firebrick, often simply referred to as firebrick, is a type of ceramic brick specifically designed for high-temperature applications, such as in industrial furnaces, kilns, fireplaces, and wood-burning stoves. These bricks are formulated to withstand extreme heat, resist thermal shock, and provide insulation in high-temperature environments.

Castables

Refractory castables, also known as refractory concrete or monolithic refractories, are a type of high-temperature refractory material made from a combination of refractory aggregates, binders, and additives. Unlike traditional refractory bricks, which are pre-formed and installed individually, refractory castables are mixed, poured, and formed in place to create a seamless lining in various high-temperature industrial equipment

Fiberglass

Refractory fiberglass, also known as refractory ceramic fibers (RCF) or aluminosilicate fibers, is a type of high-temperature insulation material made from fine ceramic fibers. These fibers are primarily composed of alumina (Al2O3) and silica (SiO2), with small amounts of other materials. Refractory fiberglass is known for its exceptional heat resistance and thermal insulation properties.

Rock wool

Refractory rock wool, often simply referred to as rock wool or mineral wool, is a type of insulation material made from natural rock, typically basalt or diabase, and other raw materials. It is processed and spun into fine fibers, forming a versatile and highly effective insulation material. While rock wool is commonly used for thermal and acoustic insulation in construction and industrial applications, “refractory” rock wool suggests a specific formulation that is designed to withstand higher temperatures and is used in high-temperature applications

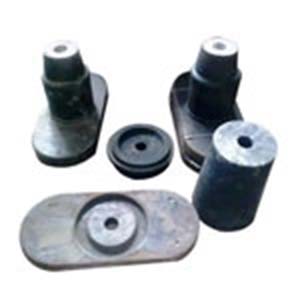

Anchors

Refractory anchors, also known as refractory anchor systems or furnace anchors, are specialized components used in the construction of refractory linings in high-temperature industrial equipment, such as furnaces, kilns, boilers, and reactors. Their primary purpose is to secure and support refractory materials, including refractory bricks, castables, and ceramic fiber linings, within these high-temperature environments. Refractory anchors play a crucial role in maintaining the integrity and longevity of refractory linings by preventing the dislodgment or shifting of refractory materials due to thermal expansion, vibration, and mechanical stress.

calcium silicate product

These products are typically composed of hydrated calcium silicate compounds, which offer several advantageous characteristics, include: Calcium Silicate Boards, pipes & Blocks, insulation blankets.

Insulation Jackets

refractory insulation jacket, also known as a refractory insulation blanket or refractory insulation wrap, is a type of insulation material or covering designed to provide thermal insulation and protection for equipment or structures operating at high temperatures. The term “refractory” in this context refers to the material’s ability to withstand extremely high temperatures without degrading or melting.

Tundish

refractory tundish is a component used in the continuous casting process of molten metal in the steelmaking industry. It plays a crucial role in controlling the flow of molten metal from the ladle to the mold, ensuring a smooth and controlled casting operation.